The slaughtering industry has seen significant advancements in technology aimed at improving efficiency, safety, and animal welfare. Modern slaughtering equipment incorporates automation, robotics, and data analytics to enhance the entire process, from pre-slaughter handling to meat processing.

Automation and Robotics

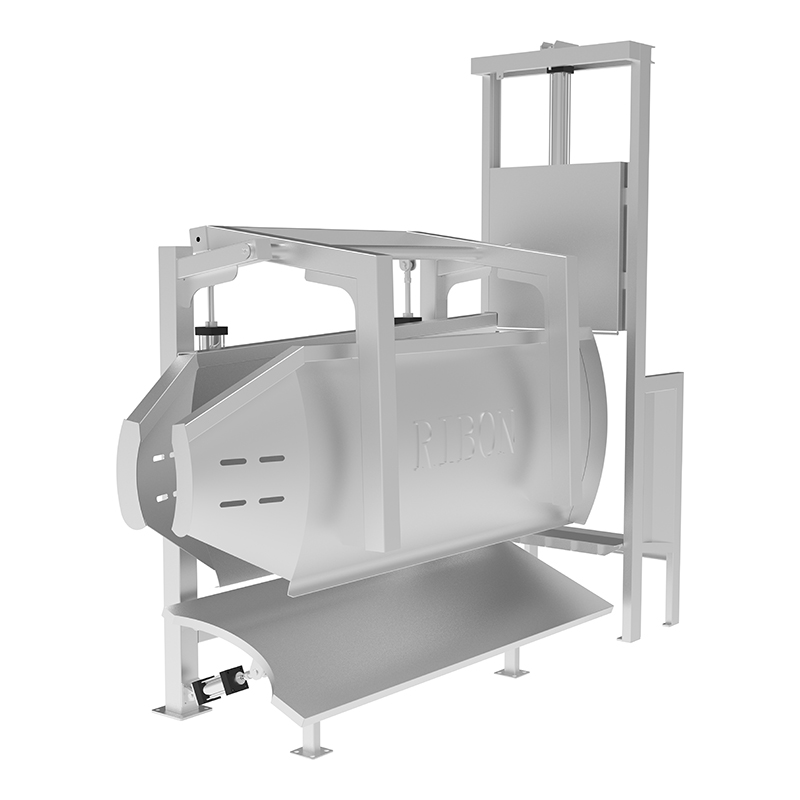

Automated systems are transforming traditional practices, allowing for higher throughput and consistency. For instance, automated stunning equipment ensures that animals are rendered unconscious quickly and humanely, minimizing stress. Robotic arms are now used for tasks such as skinning and evisceration, significantly reducing labor costs and human error. These systems can work at a consistent speed, which enhances productivity while maintaining safety standards.

Data Analytics

Integrating data analytics into slaughtering processes allows for real-time monitoring and quality control. Sensors can track animal health and welfare metrics throughout the process, ensuring compliance with regulations. Data collected can also help optimize operational efficiency by analyzing throughput rates and identifying bottlenecks in production.

Traceability and Transparency

Modern slaughtering equipment is designed to support traceability, an increasingly vital requirement in food safety. Advanced labeling and tracking systems ensure that each cut of meat can be traced back to its source, providing transparency for consumers and regulatory bodies. This capability not only enhances food safety but also builds consumer trust.

Hygiene and Safety Features

State-of-the-art slaughtering equipment incorporates features to maintain hygiene and worker safety. For example, automated cleaning systems reduce the risk of contamination by ensuring that equipment is sanitized between batches. Additionally, ergonomic designs in equipment minimize the physical strain on workers, reducing the risk of injuries and promoting a safer working environment.

Compliance with Regulations

The slaughtering industry is subject to stringent regulations that vary by region. Compliance with these regulations is crucial for operational licenses and market access. Advanced technology in slaughtering equipment helps facilities adhere to these standards by incorporating safety checks and balances, monitoring animal welfare, and ensuring humane treatment.

In summary, the integration of advanced technology in slaughtering equipment is revolutionizing the industry. Automation, data analytics, and enhanced hygiene practices not only improve efficiency but also ensure compliance with safety regulations, ultimately promoting better animal welfare and consumer confidence.

English

English русский

русский Español

Español عربى

عربى