Crate washing machines are industrial equipment designed to efficiently clean and sanitize crates used in various industries.

From food processing to manufacturing, these machines play a crucial role in maintaining hygiene and product quality.

How Crate Washing Machines Work

Crate washing machines operate on a conveyor belt system. Crates are loaded onto the conveyor and transported through a series of cleaning stages. These stages typically include:

Pre-wash: This initial stage removes loose debris and dirt from the crates.

Main wash: Powerful jets of hot water and detergent are used to break down and remove stubborn contaminants.

Rinse: Clean water removes detergent residue and other impurities.

Sanitization: This stage involves the application of a sanitizing agent to kill bacteria and germs.

Drying: Hot air or forced drying is used to remove excess water from the crates.

Benefits of Crate Washing Machines

The use of crate washing machines offers numerous advantages:

Improved hygiene: By thoroughly cleaning and sanitizing crates, the risk of contamination is significantly reduced. This is especially important in food processing and pharmaceutical industries.

Increased efficiency: Manual crate cleaning is time-consuming and labor-intensive. Crate washing machines automate the process, improving productivity and reducing labor costs.

Extended crate life: Regular cleaning helps prevent damage to crates caused by dirt and grime buildup. This extends their lifespan and reduces the need for replacements.

Cost savings: While there is an initial investment in a crate washing machine, it can lead to long-term cost savings through reduced labor, water, and detergent usage.

Compliance with regulations: Many industries have strict hygiene and sanitation regulations. Crate washing machines help ensure compliance with these standards.

Types of Crate Washing Machines

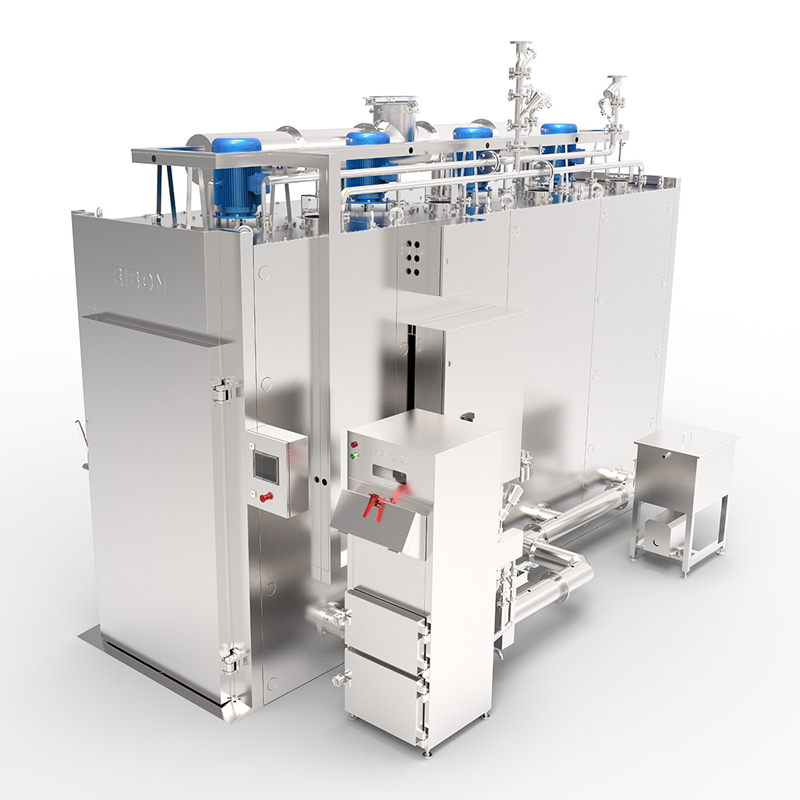

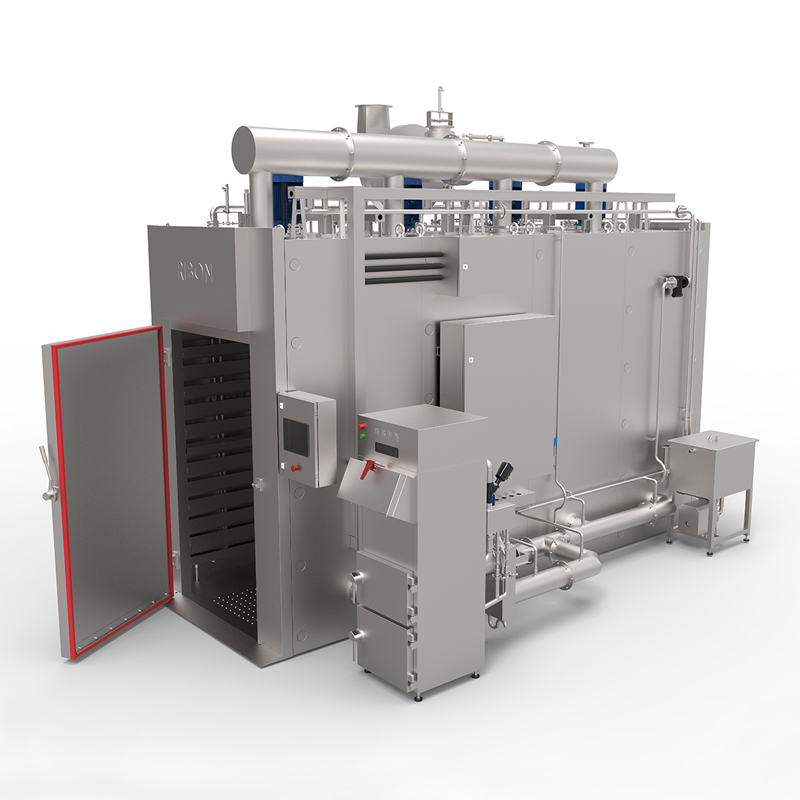

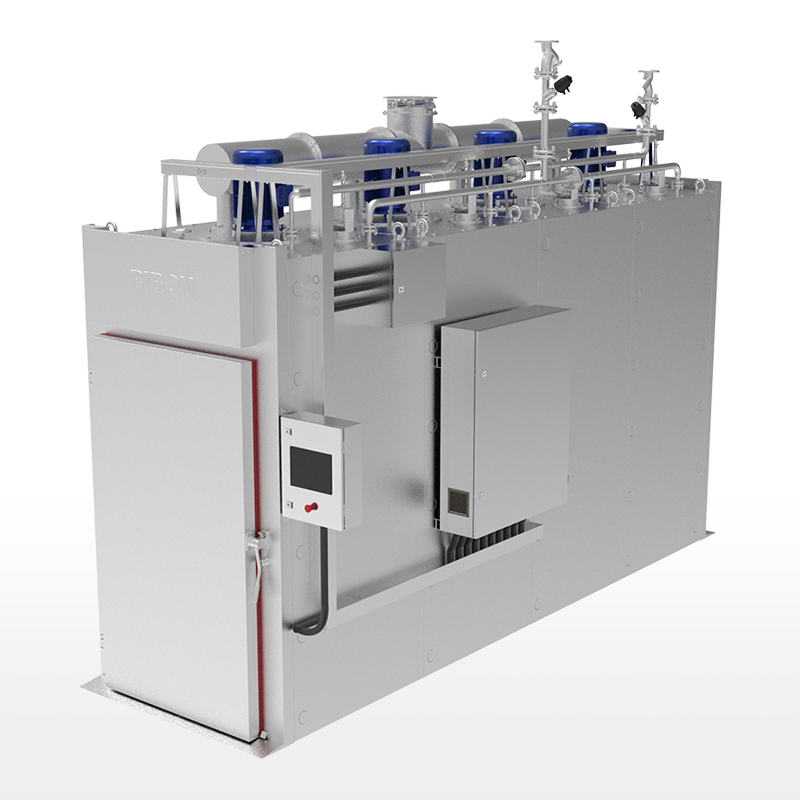

Crate washing machines come in various sizes and configurations to suit different needs. Some common types include:

Tunnel washers: These machines have a long, enclosed tunnel through which crates pass. They are suitable for high-volume operations.

Batch washers: Crates are loaded into a washing chamber and cleaned in batches. This type is often used for smaller operations or for cleaning crates of different sizes.

Custom-built washers: For specific requirements or limited space, custom-built crate washing machines can be designed.

Choosing the Right Crate Washing Machine

Selecting the appropriate crate washing machine depends on several factors:

Crate size and material: The machine must be able to accommodate the dimensions and type of crates used.

Throughput: The required cleaning capacity will determine the machine's size and speed.

Contaminant level: The type and severity of contaminants will influence the cleaning process and required equipment.

Water and energy efficiency: Consider the machine's environmental impact and operating costs.

Maintenance requirements: Easy access for cleaning and maintenance is essential.

English

English русский

русский Español

Español عربى

عربى