Meat processing smokehouses are an integral part of the culinary world, bridging tradition with modern technology to create flavorful and preserved meats. Whether it's the allure of smoked bacon, the richness of smoked sausages, or the succulence of smoked brisket, these smokehouses play a crucial role in delivering beloved delicacies to tables around the globe.

The Tradition of Smokehouses

Smokehouses have a rich history dating back centuries, where smoking was used primarily as a method of preservation. Before refrigeration, smoking meat was a practical way to extend its shelf life. The process involves exposing meat to smoke from burning or smoldering materials, which imparts complex flavors while also inhibiting bacterial growth.

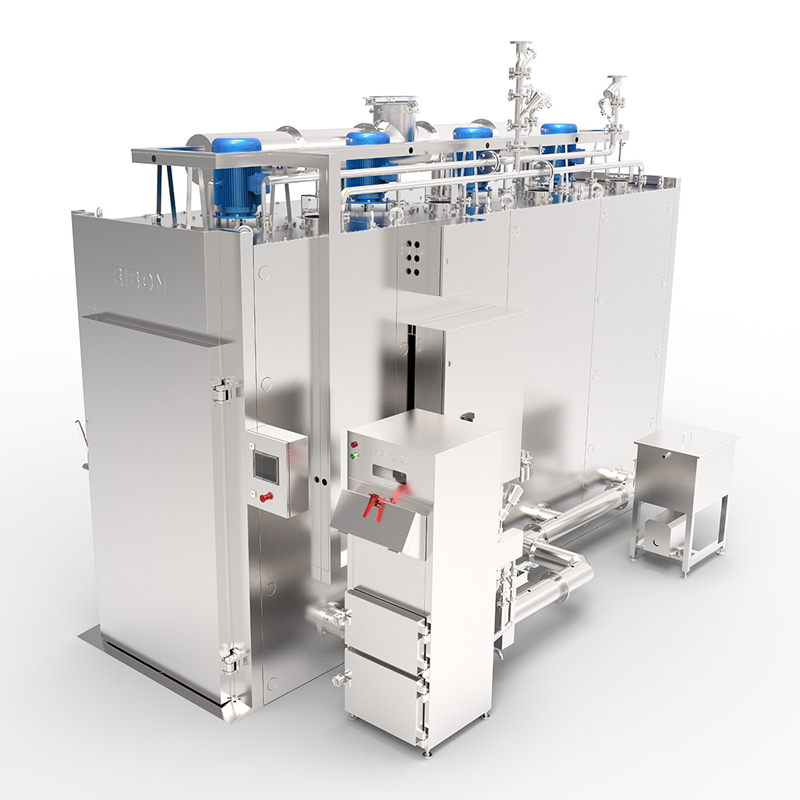

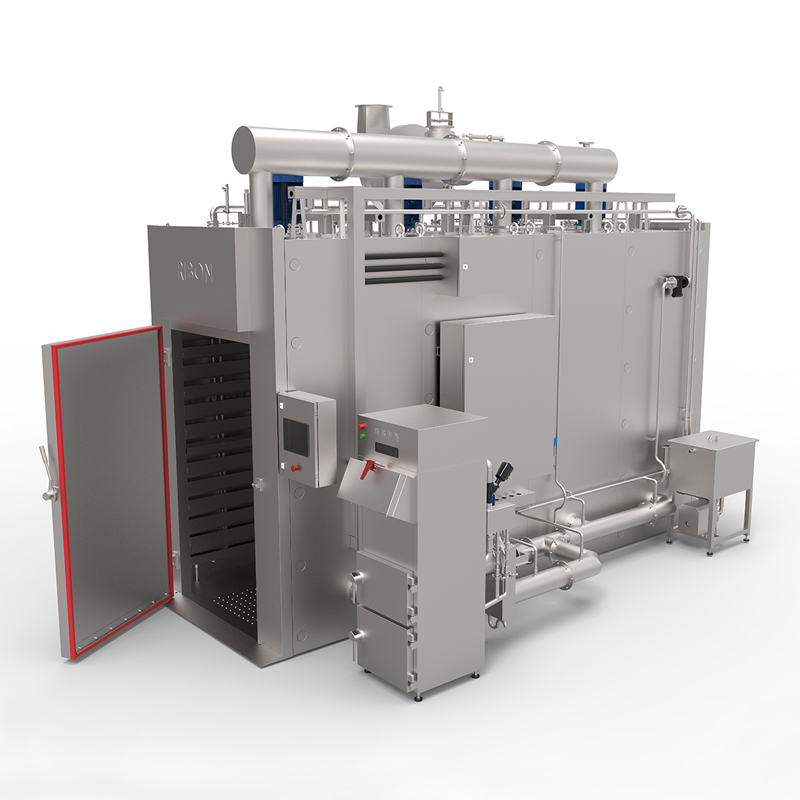

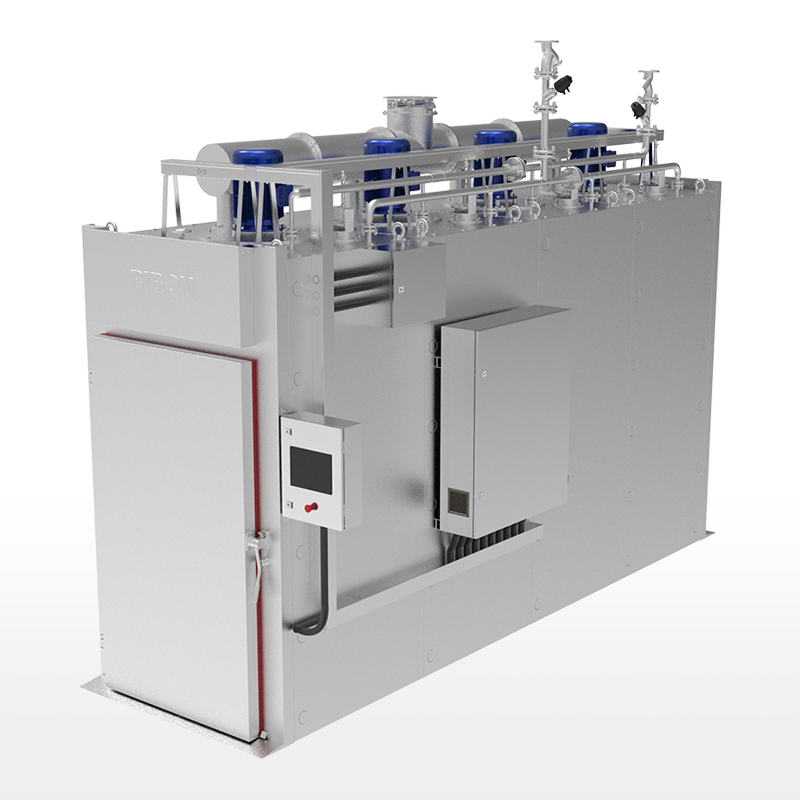

Modern Smokehouse Technology

While the fundamentals of smoking remain the same, modern smokehouses have evolved significantly in terms of efficiency, control, and safety. Advanced smokehouse technology allows for precise regulation of temperature, humidity, and smoke intensity, ensuring consistent results batch after batch. Automated systems monitor and adjust conditions, reducing the margin for error and ensuring food safety standards are met.

The Smoking Process

Meat processing smokehouses utilize various methods of smoking, including hot smoking, cold smoking, and smoke roasting, each offering distinct characteristics to the final product.

Hot Smoking: In hot smoking, meat is exposed to smoke at temperatures typically between 120°F to 180°F (50°C to 82°C). This not only imparts the desired smoky flavor but also fully cooks the meat, making it safe for consumption.

Cold Smoking: Cold smoking involves exposing meat to smoke at temperatures below 100°F (38°C). This method imparts flavor without cooking the meat, resulting in a tender yet uncooked product. Cold smoking is often followed by additional cooking methods to ensure food safety.

Smoke Roasting: Smoke roasting combines elements of both hot and cold smoking. The meat is initially exposed to low temperatures for extended periods, allowing smoke to penetrate deeply. It's then finished with a higher temperature to cook the meat thoroughly while retaining the smoky essence.

Flavor Profiles and Creativity

One of the most appealing aspects of meat processing smokehouses is the ability to experiment with flavor profiles. Different types of wood, such as hickory, mesquite, applewood, and cherry, impart distinct flavors to the meat. Additionally, chefs often incorporate herbs, spices, and marinades to enhance the final product's taste and aroma, resulting in a myriad of delicious possibilities.

English

English русский

русский Español

Español عربى

عربى