In the dynamic world of food processing, innovation plays a crucial role in ensuring quality, efficiency, and customer satisfaction. One such groundbreaking innovation is the vacuum tumbler, a device that has significantly transformed the meat processing industry.

Understanding Vacuum Tumblers

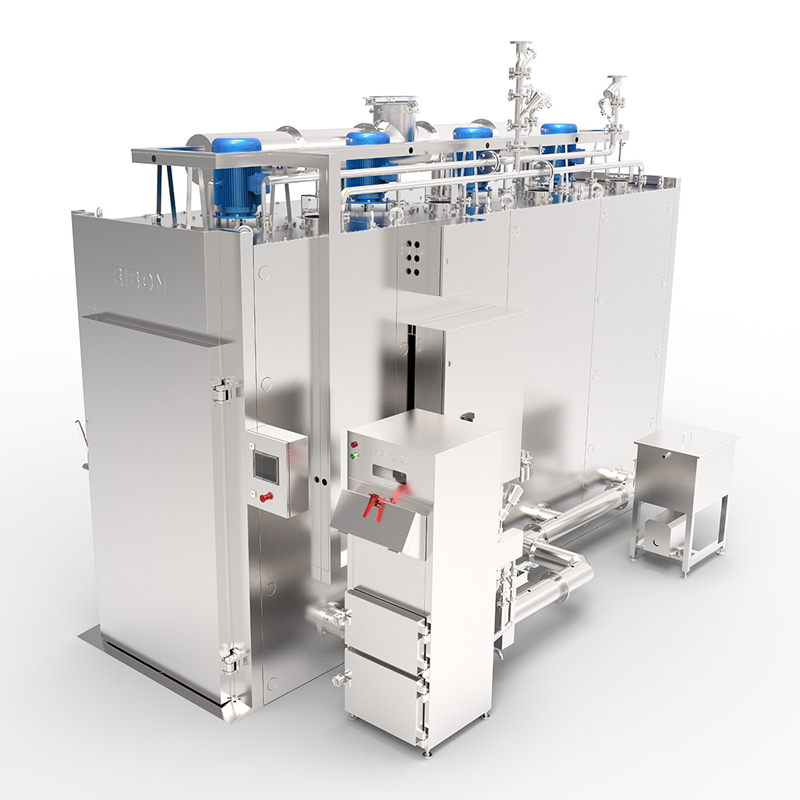

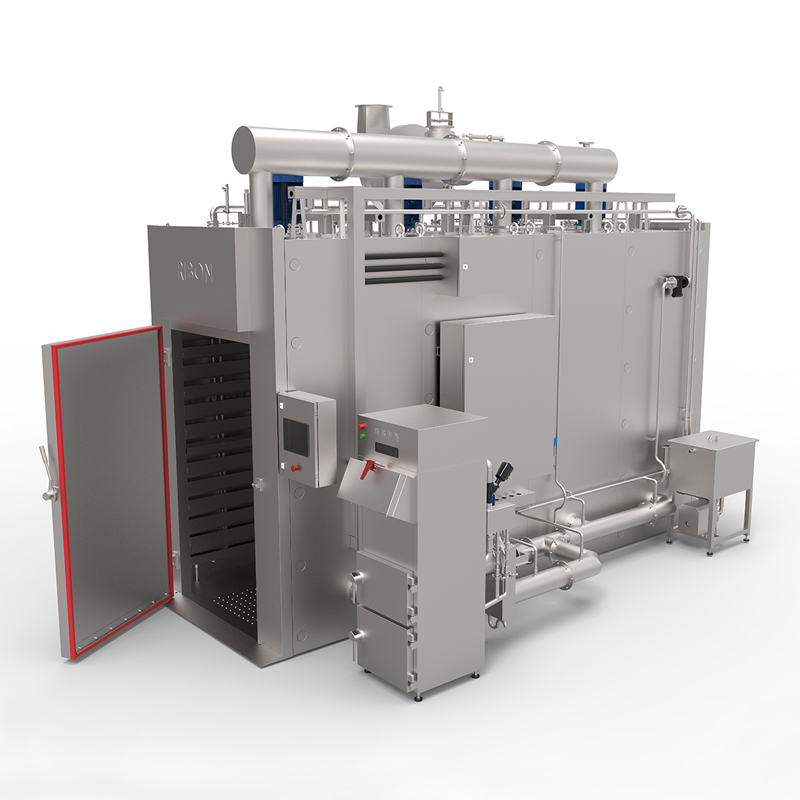

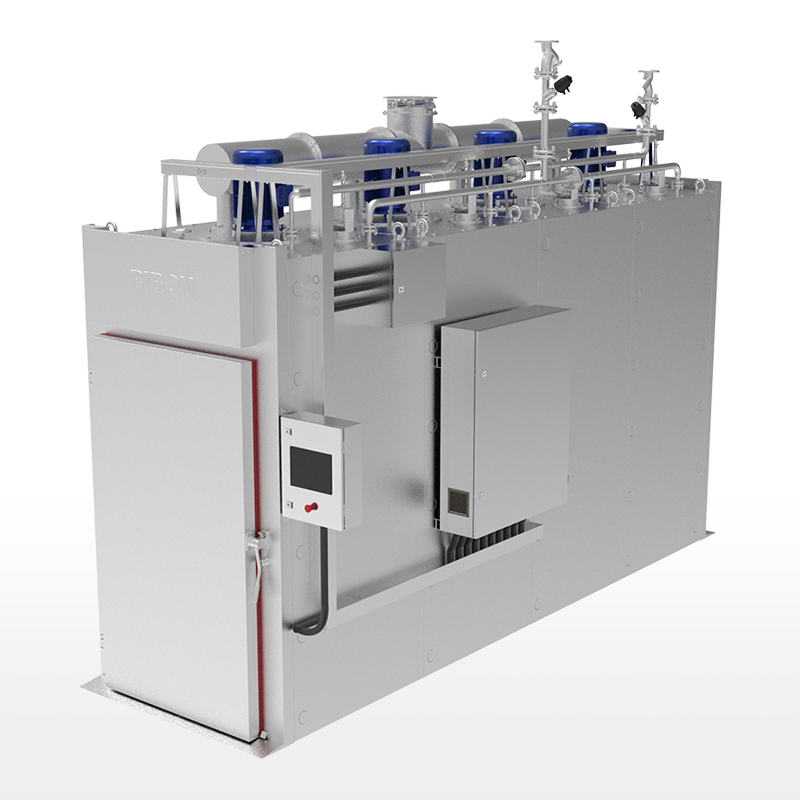

A vacuum tumbler is a specialized machine used primarily in the meat processing industry to marinate and tenderize meat products. Unlike traditional tumbling methods, vacuum tumblers operate under low-pressure conditions, enhancing the absorption of marinades and spices into the meat. The process involves placing the meat and marinade into the tumbler's drum, which is then sealed and the air removed to create a vacuum environment. The drum rotates, allowing the meat to tumble and ensuring an even distribution of the marinade.

How Vacuum Tumblers Work

The vacuum environment created within the tumbler significantly impacts the meat's texture and flavor. Here’s a closer look at the process:

Vacuum Creation: By removing air from the tumbler, the machine creates a low-pressure environment. This vacuum state causes the meat fibers to expand, opening up and allowing the marinade to penetrate deeply.

Tumbling Action: The rotating drum gently agitates the meat, ensuring that the marinade is evenly distributed. This action also helps to break down muscle fibers, making the meat more tender.

Enhanced Absorption: The combination of vacuum pressure and tumbling action ensures that the marinade infuses more thoroughly into the meat compared to traditional methods, leading to enhanced flavor and improved moisture retention.

Benefits of Using Vacuum Tumblers

The use of vacuum tumblers offers numerous advantages over conventional marinating and tenderizing methods:

Improved Flavor and Texture: Vacuum tumbling allows for better absorption of marinades, resulting in more flavorful and tender meat. The even distribution of spices and seasonings ensures consistent taste throughout the meat.

Reduced Marinating Time: Traditional marinating methods can take hours or even days to achieve the desired flavor. Vacuum tumblers significantly reduce this time, often achieving the same results in a matter of minutes to a few hours.

Increased Product Yield: By enhancing moisture retention, vacuum tumblers help increase the overall yield of the meat. This means less shrinkage during cooking, leading to higher profitability for processors.

Enhanced Food Safety: The vacuum environment minimizes the risk of bacterial contamination, leading to safer, more hygienic food products.

Cost-Effective Production: The efficiency of vacuum tumblers can lead to lower operational costs. Faster marinating times and increased yield contribute to more cost-effective production processes.

Applications in the Food Industry

Vacuum tumblers are primarily used in the meat processing industry, but their applications extend to various other sectors within food production:

Meat Processing: From beef and pork to poultry and seafood, vacuum tumblers are used to marinate, tenderize, and flavor a wide range of meat products. They are particularly popular in the production of deli meats, sausages, and marinated cuts.

Prepared Foods: Ready-to-eat meals and prepared food products benefit from the enhanced flavor and texture provided by vacuum tumblers. The machines ensure that these products are consistently delicious and tender.

Marinated Vegetables: While less common, vacuum tumblers can also be used to marinate vegetables, infusing them with spices and seasonings for a unique and flavorful culinary experience.

English

English русский

русский Español

Español عربى

عربى