In the realm of culinary innovation and food processing, vacuum tumblers stand out as indispensable tools, particularly when it comes to elevating the flavor and quality of marinated meats. These mechanical marvels are not just about convenience; they are about precision, efficiency, and the creation of tantalizing culinary experiences.

The primary allure of vacuum tumblers lies in their ability to coax marinades deep into the fibers of meat. The vacuum environment created within the tumbler drum is key here, as it effectively removes air pockets from the meat, allowing the marinade to penetrate every nook and cranny. This thorough infusion of flavors results in meat that doesn't just taste good on the surface but is bursting with deliciousness throughout.

Tough cuts of meat can be transformed into succulent delights with the help of vacuum tumblers. As the drum rotates and the vacuum pressure is applied, the meat undergoes gentle massaging and tenderization. This process not only breaks down connective tissues but also allows the marinade to work its magic, further enhancing the meat's tenderness and juiciness.

Time is of the essence in commercial kitchens and food processing facilities. Vacuum tumblers excel in streamlining the marination process, significantly reducing the time required compared to traditional methods. Within a short span, these machines can turn raw meat into flavor-infused masterpieces, ready to delight the palate.

Consistency is the hallmark of professional cooking, and vacuum tumblers deliver on this front. By ensuring uniform marinade distribution and tenderization, these devices guarantee that every batch of marinated meat maintains the same high standard of flavor and texture. This level of consistency is crucial for meeting customer expectations and building a reputation for excellence.

Optimizing marinade usage is not just about flavor; it's also about efficiency and cost-effectiveness. Vacuum tumblers minimize marinade wastage by maximizing absorption into the meat, translating into cost savings over time. This reduction in supply costs, coupled with improved product quality, contributes to overall profitability in food processing operations.

Vacuum tumblers are not limited to specific types of meat or marinades. Whether it's beef, poultry, pork, or seafood, these machines can handle a wide range of food products with ease. Additionally, they accommodate various marinade types, from simple herb blends to complex flavor concoctions, allowing chefs and food processors to unleash their creativity.

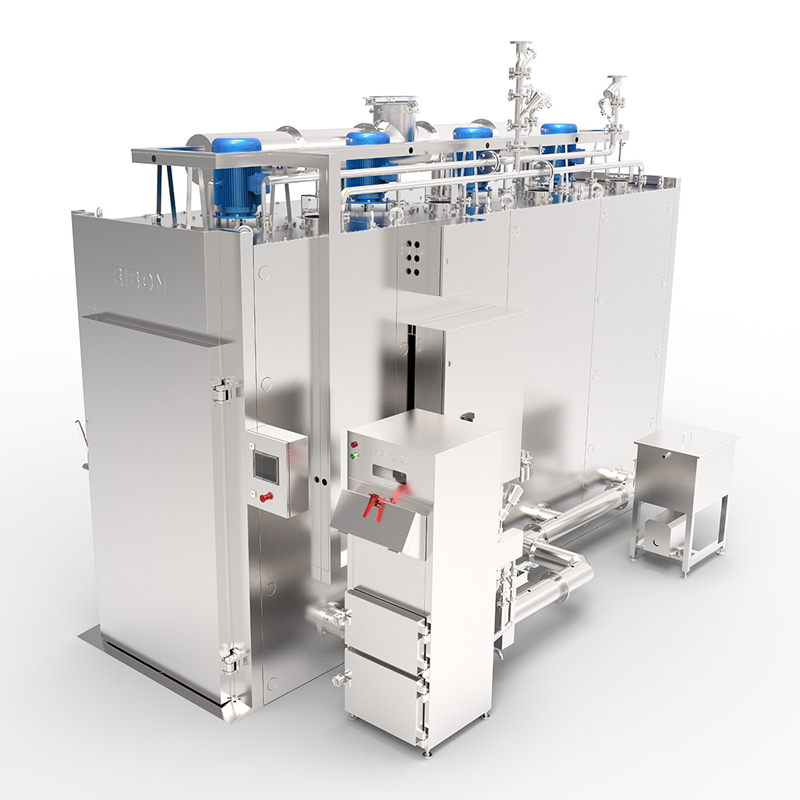

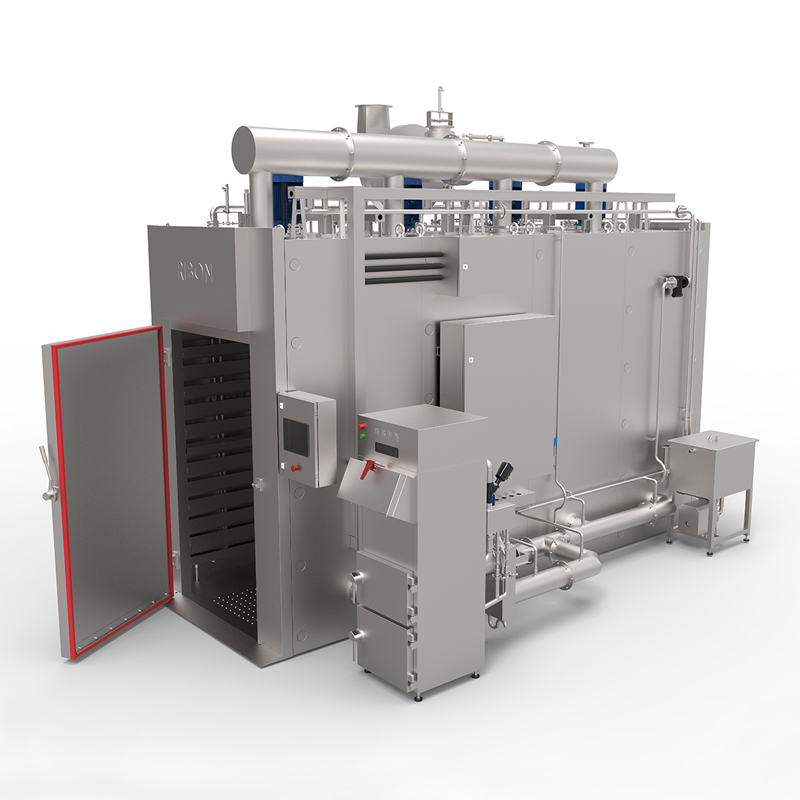

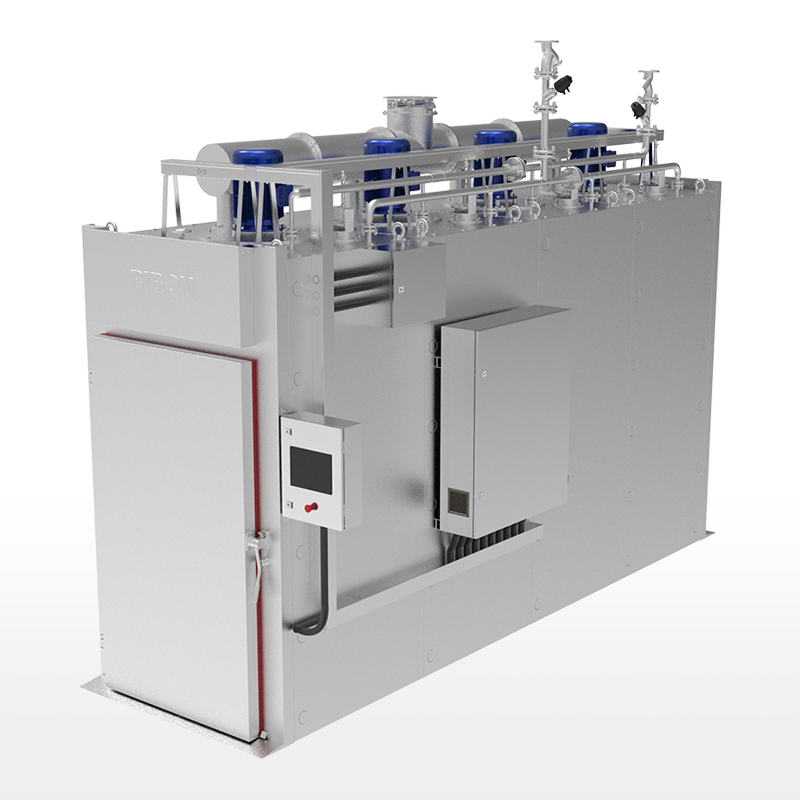

Despite their advanced capabilities, vacuum tumblers are designed for user-friendly operation. Modern models come equipped with intuitive controls, safety features, and easy-to-clean components, making them suitable for both professional kitchens and small-scale operations.

English

English русский

русский Español

Español عربى

عربى