The Science of Smoking: How Equipment Affects Flavor

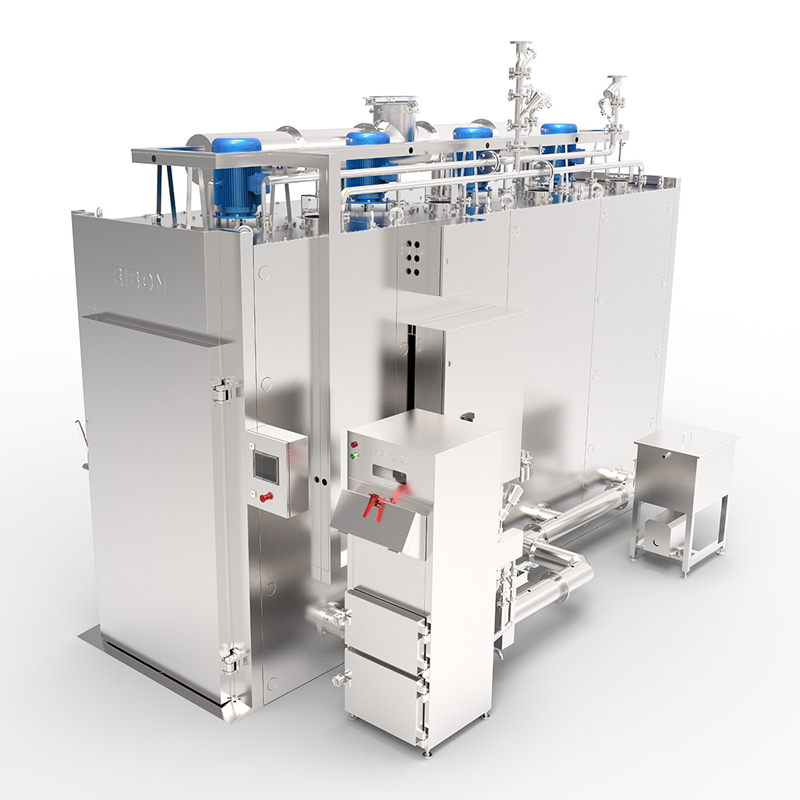

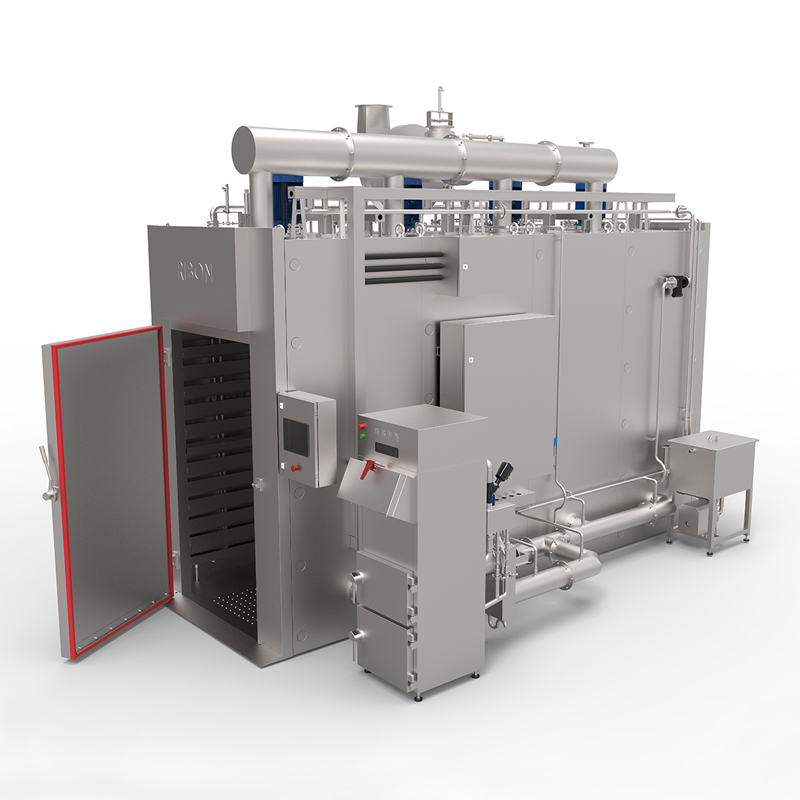

Wood Type and Smoke Generators: One of the primary contributors to flavor in smoked meat is the type of wood used for smoking. Different woods, such as hickory, mesquite, applewood, and cherry, impart their unique flavors into the meat. The smoke generator, which burns wood chips or pellets, is a key factor in how the flavor is transferred to the meat. High-quality generators allow for a steady and controlled release of smoke, ensuring the flavor is evenly distributed.

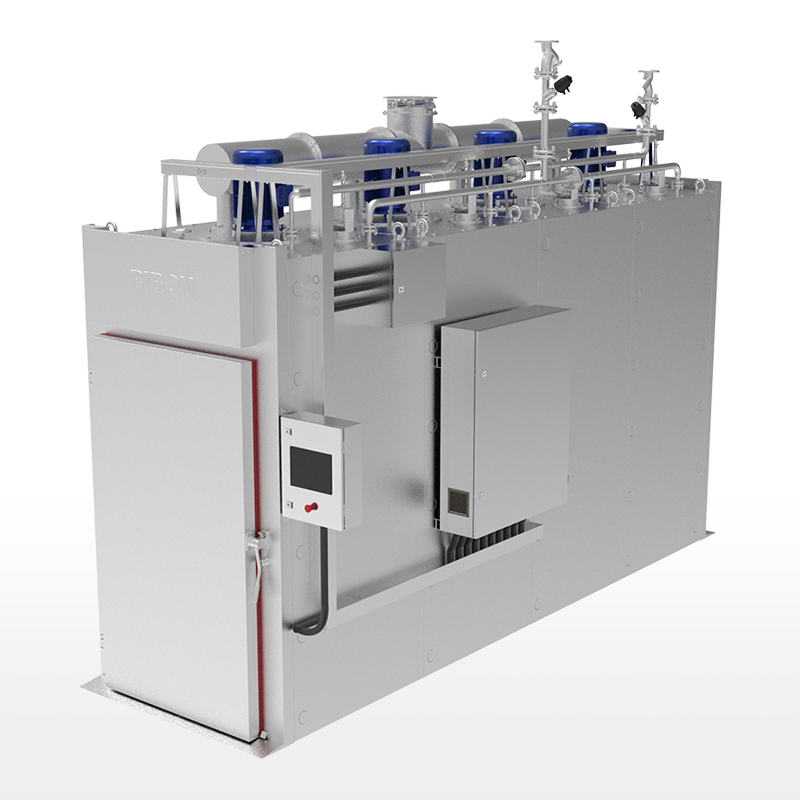

Temperature Control: Smoking is typically a slow process, where meat is cooked at low temperatures for long periods. If the temperature is too high, the meat may become overcooked, resulting in dry and tough textures. On the other hand, if the temperature is too low, the smoking process may take too long, leading to inconsistent flavor infusion. Smoking house equipment with precise temperature control ensures that meat is smoked at the ideal temperature for both flavor development and preservation.

Humidity Regulation: The ideal humidity levels in a smoker are crucial for maintaining moisture within the meat while allowing for proper smoking. Humidity control also affects how the meat absorbs smoke. Too much humidity can prevent the smoke from adhering to the meat's surface, while too little can dry out the meat and affect the final texture. Advanced smoking house equipment integrates humidity regulation to ensure optimal conditions for flavor absorption and preservation.

Air Circulation: Proper airflow is necessary to ensure that smoke circulates evenly around the meat. Without adequate air circulation, certain parts of the meat might be over-smoked, while others remain under-smoked. The airflow system in modern smoking houses ensures that smoke evenly coats the surface of the meat, leading to a uniform flavor throughout.

Meat Preservation: How Smoking Houses Extend Shelf Life

Curing and Smoking: One of the main benefits of smoking meat is its ability to preserve food for longer periods. Smoking meat not only enhances its flavor but also reduces moisture, which helps prevent bacterial growth. Smoking house equipment with precise control over time and temperature ensures the meat undergoes proper curing, drying, and smoking processes that extend its shelf life.

Antimicrobial Properties: The smoke itself contains various chemicals that have natural preservative properties, including phenols and acids. These compounds act as natural preservatives, helping to protect the meat from spoilage. High-quality smoke generators are designed to produce consistent smoke, ensuring that meat remains preserved for extended periods without the need for artificial preservatives.

Vacuum Sealing and Packaging: Many modern smoking houses are equipped with vacuum sealing and packaging systems. After the meat has been smoked, it can be immediately vacuum-sealed to ensure freshness and further extend its shelf life. Packaging technology helps keep the smoked meat free from contaminants, preserving its flavor and quality until it reaches the consumer.

The Role of Technology in Flavor and Preservation

Digital Monitoring and Control: The rise of digital monitoring systems has greatly enhanced the precision of smoking processes. Operators can now monitor key factors like temperature, humidity, and smoke intensity in real-time, allowing for adjustments as needed. This level of control ensures that every batch of meat is smoked to perfection, with consistent flavor profiles and optimal preservation conditions.

Automation and Efficiency: With automated features like temperature regulation, smoke generation, and humidity control, modern smoking houses can produce large quantities of smoked meat without sacrificing flavor or quality. Automation also reduces the risk of human error, ensuring that the preservation process is consistent and reliable.

English

English русский

русский Español

Español عربى

عربى