Why Sustainability Matters in Meat Processing

The meat processing industry is one of the most resource-intensive sectors, requiring significant amounts of water, energy, and raw materials. Additionally, the environmental impact of waste, emissions, and packaging waste is a growing concern. Consumers are more conscious than ever about the sustainability practices of the brands they purchase from, pushing businesses to adopt greener technologies and processes.

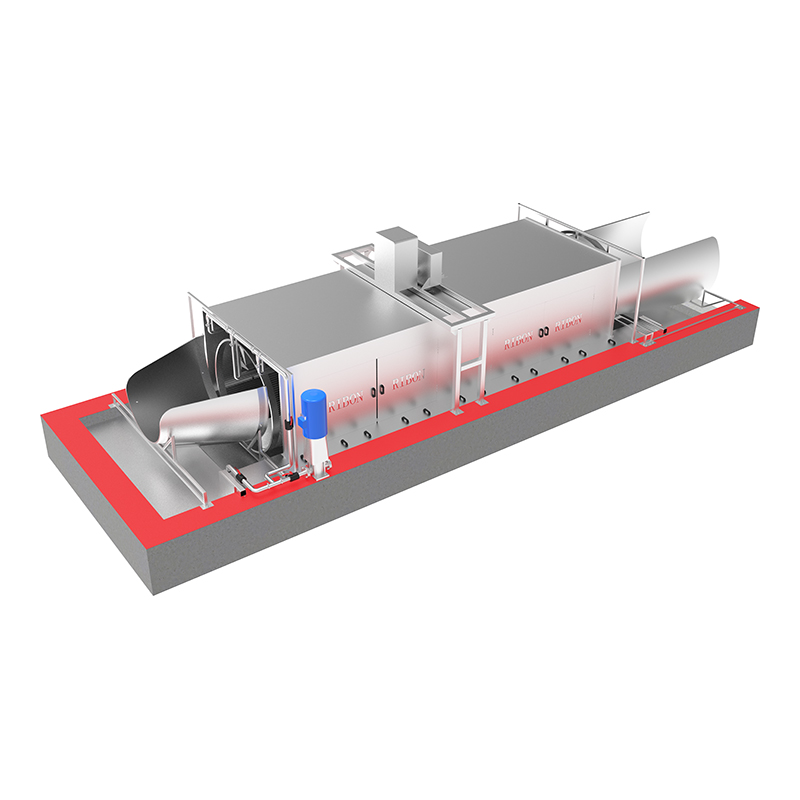

Energy Efficiency in Meat Processing Machinery

One of the key areas where sustainability can be achieved in meat processing is through energy efficiency. Many modern machines are designed to consume less energy, reducing the carbon footprint of meat processing plants. High-efficiency motors, variable speed drives, and advanced control systems help optimize energy use while maintaining peak performance.

For example, meat grinders and mixers now come equipped with energy-saving features that adjust the speed of operation based on load requirements. By reducing energy consumption during less demanding tasks, businesses can lower their operational costs and minimize their environmental impact.

Waste Reduction and Resource Optimization

Meat processing generates a significant amount of waste, including bones, fat, and other byproducts. Many manufacturers are investing in machinery designed to minimize waste and utilize these byproducts in innovative ways. For example, advanced grinding and cutting machines can achieve higher yields from each animal, reducing the amount of meat that goes to waste.

Additionally, many companies are looking into ways to repurpose waste for other industries. For instance, animal byproducts are often used in pet food production, biofuel generation, or even in the creation of biodegradable plastics. By reusing waste materials, meat processors can contribute to a more circular economy.

Sustainable Packaging Solutions

Packaging is another critical aspect of sustainability in the meat processing industry. Traditionally, meat packaging has relied heavily on plastic, but advances in packaging machinery are making it easier for businesses to adopt more sustainable options. For example, modified atmosphere packaging (MAP) machines can now use biodegradable or recyclable materials, reducing plastic waste.

The development of smart packaging technologies also allows for longer shelf life without the need for excessive preservatives, further reducing food waste.

Water Conservation in Meat Processing

Water is essential to meat processing, but it is also a resource that needs to be used efficiently. Many meat processing machines now incorporate water-saving features, such as closed-loop systems that recycle water used in cooling and cleaning processes. By reusing water, businesses can reduce their water consumption and minimize waste.

English

English русский

русский Español

Español عربى

عربى