Stunning Devices:

The first step in cattle slaughtering involves rendering the animal unconscious through stunning. Captive bolt pistols, electrical stunners, and carbon dioxide chambers are among the most widely used methods today. Captive bolt pistols deliver a precise blow to the animal’s brain, instantly knocking it out. Electrical stunners pass a controlled current through the animal’s body, inducing unconsciousness within seconds. Meanwhile, carbon dioxide chambers immerse animals in gas, gradually rendering them unconscious. Each method is carefully regulated to ensure minimal distress and adherence to animal welfare laws.

Bleeding Systems:

Once the animal is stunned, it moves to the bleeding station. Here, specialized equipment facilitates the rapid and hygienic removal of blood. Modern bleeding systems often include stainless steel platforms, conveyor belts, and automated cutting tools. Some advanced models incorporate vacuum suction technology to collect blood efficiently, preventing spillage and contamination. Proper bleeding is vital for producing high-quality meat, as residual blood can lead to spoilage and off-flavors.

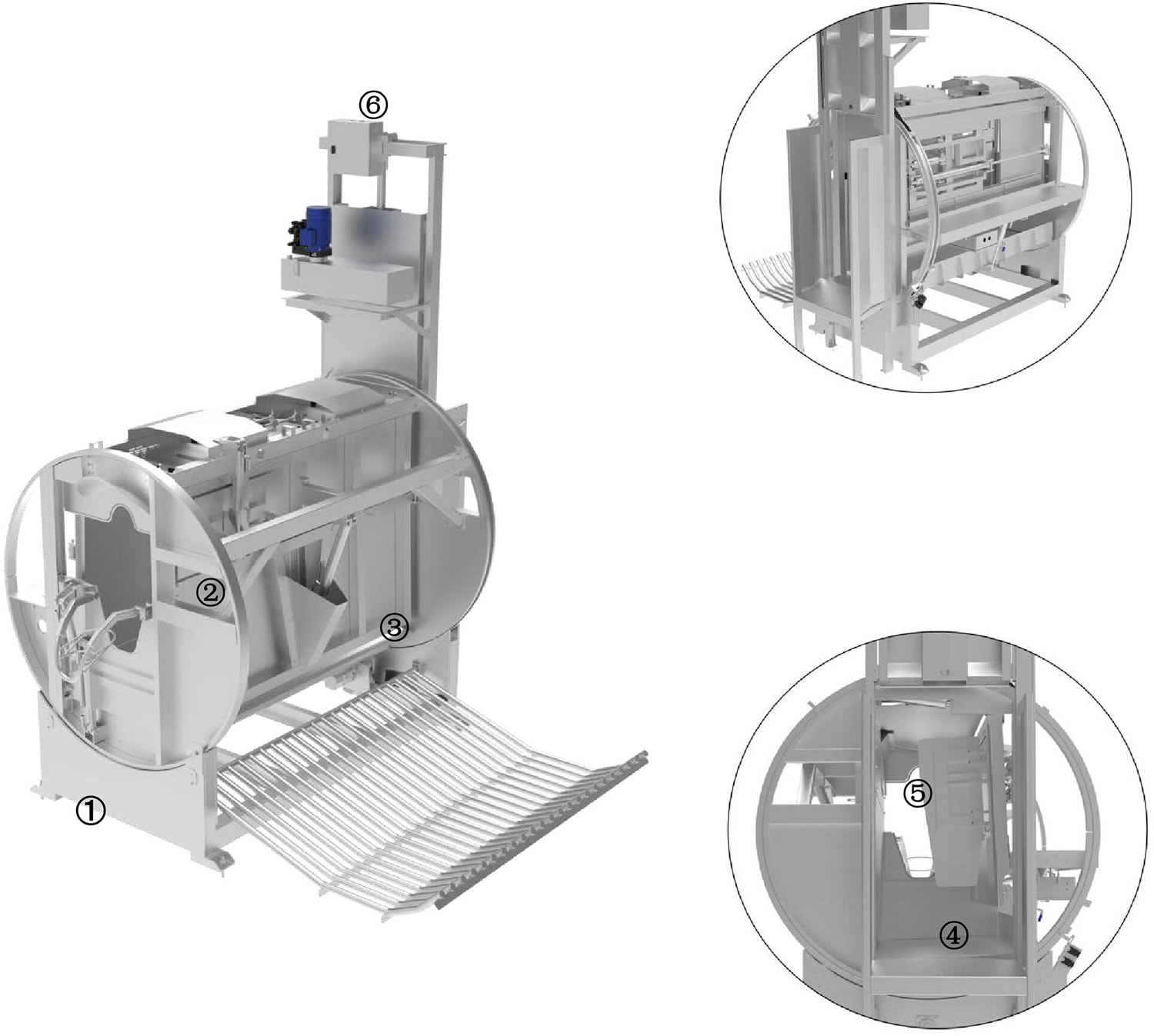

Skinner Machines:

After bleeding, the next step is skinning. Skinner machines have become indispensable in large-scale operations due to their speed and accuracy. These machines typically feature rotating drums or blades that grip and peel away the hide from the carcass. Some models are equipped with adjustable settings to accommodate varying sizes of cattle. The result is a clean separation of the hide, which can then be processed separately for leather production.

Evisceration Equipment:

Evisceration is one of the most delicate steps in cattle processing, requiring careful handling to avoid contaminating the meat. Evisceration equipment uses mechanical arms or conveyor systems to remove internal organs systematically. Sensors and cameras may be integrated into these machines to detect abnormalities or defects in the organs, ensuring only healthy carcasses proceed to the next stage. This equipment also helps segregate edible offal (such as liver and kidneys) from non-edible waste, optimizing resource utilization.

Deboning and Cutting Machines:

For processors focused on value-added products, Cattle Slaughtering Equipment are invaluable. These machines utilize sharp blades, saws, and robotic arms to separate meat from bones and produce consistent cuts. Advanced software allows operators to program specific cuts, catering to diverse market demands. For example, some machines specialize in creating steaks, roasts, or ground beef, while others focus on niche items like filet mignon.

Sanitation and Waste Management Systems:

Hygiene is paramount in cattle slaughtering facilities, making sanitation equipment a critical component. High-pressure washers, steam cleaners, and chemical disinfectants are commonly employed to sanitize surfaces and tools. Additionally, waste management systems help dispose of unusable parts, such as bones, fat, and entrails, in an environmentally friendly manner. Many facilities now implement composting or bioconversion techniques to turn organic waste into fertilizer or feedstock.

English

English русский

русский Español

Español عربى

عربى