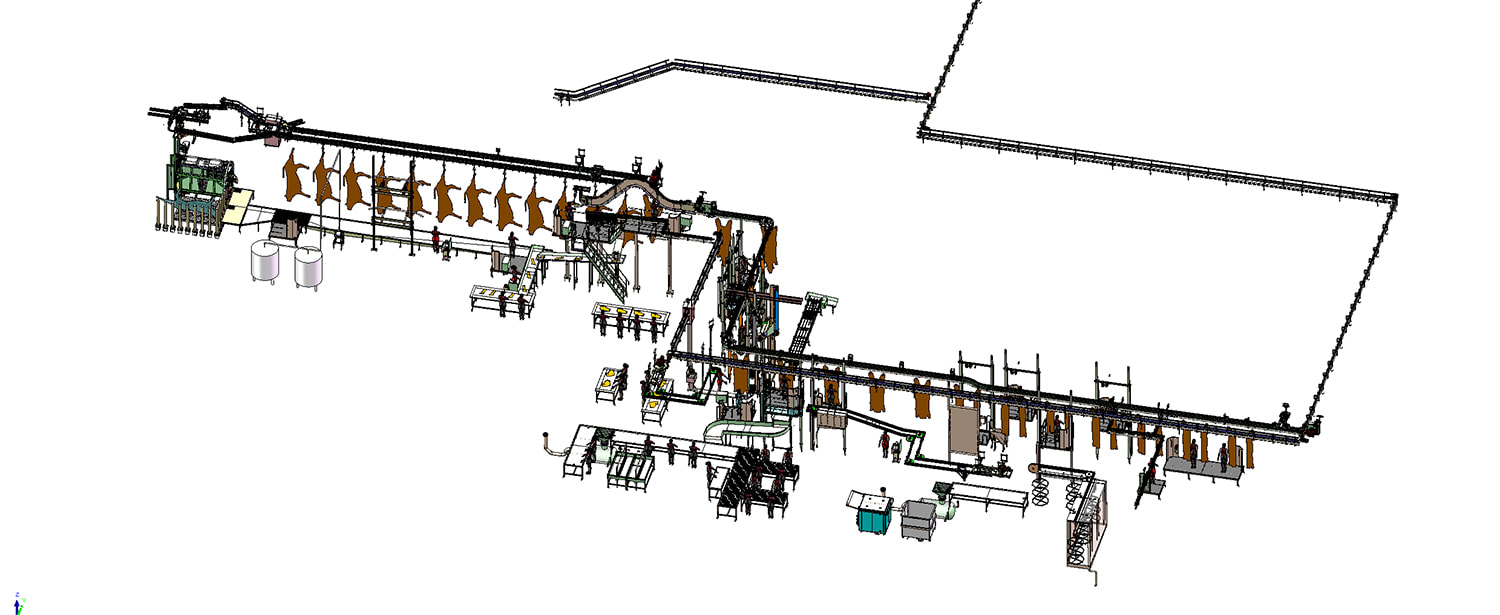

The cattle slaughtering industry has long relied on manual labor and basic tools to process animals for meat production. However, the advent of advanced technology has revolutionized this sector, introducing equipment that not only improves efficiency but also enhances safety, hygiene, and animal welfare. As the global demand for high-quality meat continues to rise, the integration of cutting-edge technology into cattle slaughtering processes has become indispensable.

One of the most significant technological advancements in recent years is the use of automated stunning systems . These systems replace traditional methods like manual captive bolt pistols with precision-engineered devices that ensure consistent and humane stunning. For instance, electrical stunning systems are now equipped with programmable settings that adjust voltage and current based on the size and breed of the animal. This customization minimizes the risk of under-stunning or over-stunning, ensuring compliance with animal welfare regulations. Similarly, CO2 stunning chambers have been upgraded with sensors that monitor gas concentration levels in real time, guaranteeing optimal conditions for rendering animals unconscious.

Another area where technology has made a profound impact is in precision cutting and deboning equipment . Modern machinery uses computer-aided design (CAD) and artificial intelligence (AI) to map out the anatomy of cattle carcasses, enabling precise cuts that maximize yield while minimizing waste. Robotic arms equipped with laser-guided blades can identify and separate different muscle groups with remarkable accuracy. This level of precision is particularly valuable for premium cuts such as ribeye or tenderloin, which command higher prices in the market. Additionally, automated deboning machines reduce the need for human intervention, lowering the risk of contamination and workplace injuries.

Technology has also played a pivotal role in improving sanitation and hygiene standards within slaughterhouses. High-pressure washing systems and ultraviolet (UV) disinfection units are now standard features in many facilities. These systems eliminate pathogens and bacteria from surfaces, tools, and even the air, significantly reducing the risk of foodborne illnesses. Some advanced sanitation equipment incorporates IoT sensors that monitor cleanliness levels and alert operators when re-cleaning is necessary. Furthermore, water recycling systems have been developed to conserve resources while maintaining rigorous hygiene protocols.

The incorporation of data analytics into cattle slaughtering operations represents another leap forward. By collecting and analyzing data at every stage of the process—from stunning to packaging—manufacturers can identify inefficiencies and implement corrective measures. For example, machine learning algorithms can predict maintenance needs for equipment, preventing costly breakdowns and downtime. Data-driven insights also enable producers to optimize workflows, reduce energy consumption, and improve overall productivity. In some cases, blockchain technology is being used to create transparent supply chains, allowing consumers to trace the origin of their meat products back to the farm.

Despite these advancements, the adoption of technology in cattle slaughtering equipment comes with its own set of challenges. One major hurdle is the initial cost of investment, which can be prohibitive for smaller processors. To address this issue, manufacturers are exploring modular designs that allow facilities to upgrade incrementally rather than replacing entire systems at once. Leasing options and government incentives for sustainable practices are additional strategies being employed to make advanced equipment more accessible.

Another challenge is the need for skilled personnel to operate and maintain sophisticated machinery. Training programs and certifications are becoming increasingly important to equip workers with the knowledge required to handle new technologies effectively. Equipment manufacturers are also investing in user-friendly interfaces and intuitive controls to simplify operation and troubleshooting.

Looking ahead, the future of cattle slaughtering equipment lies in further innovation and sustainability. Researchers are experimenting with biodegradable materials for machine components, as well as renewable energy sources to power equipment. Augmented reality (AR) and virtual reality (VR) are emerging as potential tools for training and simulation, offering immersive experiences that enhance learning outcomes.

English

English русский

русский Español

Español عربى

عربى