How does the self-cleaning system of the atomizer function?

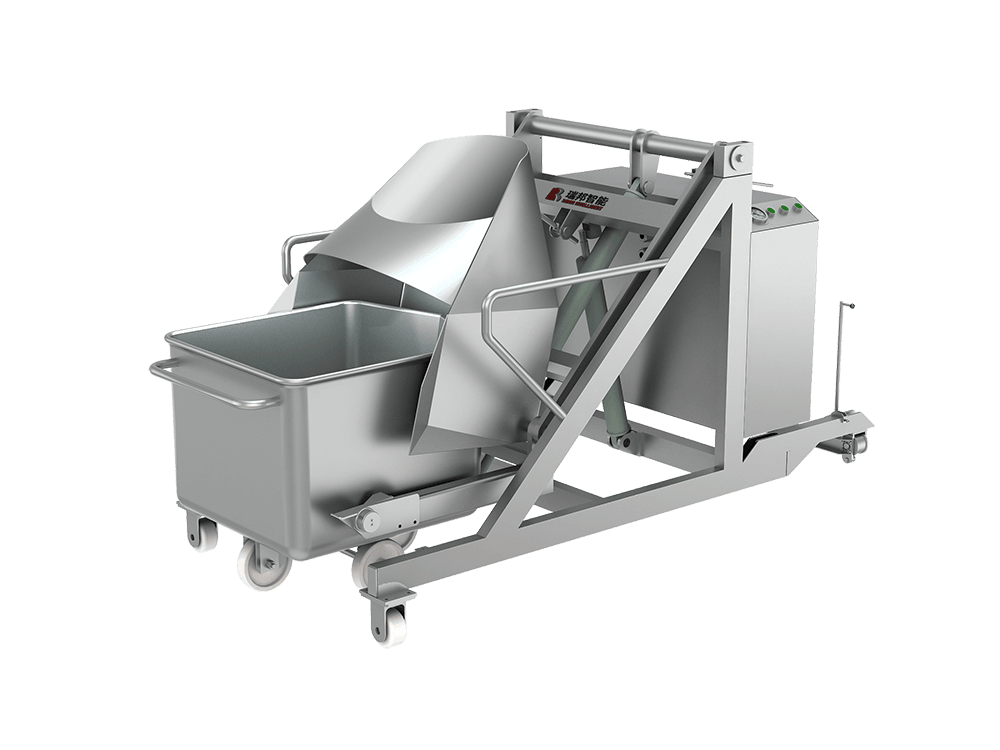

The self-cleaning system of a

liquid smoke atomizer is designed to remove residue and buildup from the atomization chamber and other components automatically, without the need for manual intervention. The exact mechanism of self-cleaning can vary depending on the design and technology used by the manufacturer, but here is a general overview of how it might function:

Automated Cleaning Cycle: The atomizer is equipped with sensors or timers that initiate a cleaning cycle after a certain number of smoking sessions or at scheduled intervals. Alternatively, the cleaning cycle may be manually activated by the user through a control panel or app interface.

Purge of Residual Smoke: Before cleaning begins, the atomizer purges any remaining liquid smoke or smoke particles from the atomization chamber and associated conduits. This ensures that the cleaning solution can effectively remove any stubborn residue.

Cleaning Solution Injection: A cleaning solution, typically a mixture of water and detergent or a specialized cleaning agent, is injected into the atomization chamber and circulated through the system. The cleaning solution helps to dissolve and dislodge any accumulated residue, tar, or impurities from the internal surfaces of the atomizer.

Agitation or Ultrasonic Cleaning: Some advanced atomizers may incorporate mechanisms for agitation or ultrasonic cleaning during the cleaning cycle. These methods help to break down stubborn deposits and ensure thorough cleaning of all components, including nozzles, valves, and filters.

Rinsing and Drainage: After the cleaning solution has circulated through the system for a specified period, it is flushed out, along with the loosened debris and contaminants. The atomizer may include drainage channels or ports to facilitate the removal of the spent cleaning solution and residue.

Drying Process: Once the cleaning cycle is complete, the

Meat Processing Liquid Smoke Atomizer may engage a drying process to remove any remaining moisture from the internal components. This helps to prevent the growth of mold or bacteria and ensures that the atomizer is ready for the next smoking session.

Status Indicators: Throughout the cleaning cycle, the atomizer may provide visual or audible indicators to inform the user of the progress and status of the cleaning process. This allows users to monitor the operation and ensure that the atomizer is functioning correctly.

How does the Liquid Smoke Atomizer work?

Liquid Smoke Preparation: The liquid smoke used in the atomizer is typically a concentrated solution derived from the condensation of natural wood smoke. It may contain water, wood smoke extract, natural flavors, and other additives.

Atomization Process: The liquid smoke is introduced into the atomization chamber of the device. Within this chamber, the liquid is subjected to controlled pressure or ultrasonic vibrations, breaking it down into tiny droplets or particles.

Heating Element (Optional): In some

liquid smoke atomizers, a heating element may be used to vaporize the liquid smoke particles, creating a fine mist or vapor. This vaporization process enhances the flavor and aroma of the smoke and may also contribute to a smoother inhalation experience.

Delivery Mechanism: Once atomized, the liquid smoke particles are propelled through a delivery system, which may include tubes, nozzles, or cartridges. This system directs the atomized smoke to the desired location, such as a smoking chamber, food product, or inhalation device.

Control Mechanisms: Modern liquid smoke atomizers often feature smart control mechanisms that allow users to adjust parameters such as concentration, flow rate, and temperature. These controls enable customization of the smoking experience and ensure consistent flavor and performance.

Safety Features: To ensure user safety,

Meat Processing Liquid Smoke Atomizer may incorporate safety mechanisms such as overheat protection, leak detection, and automatic shut-off functions. These features help to prevent accidents and ensure reliable operation.

Cleaning and Maintenance: Some liquid smoke atomizers include self-cleaning systems, as discussed earlier, which help to remove residue and buildup from the atomization chamber and other components. Regular maintenance is essential to ensure optimal performance and hygiene.