The Essential Guide to Home Smoking Equipment: Mastering the Art of Smoke

The Allure of Smoke: Why Home Smoking is on the Rise The practice of smoking food—curing and flavoring it through exposu...

READ MORE

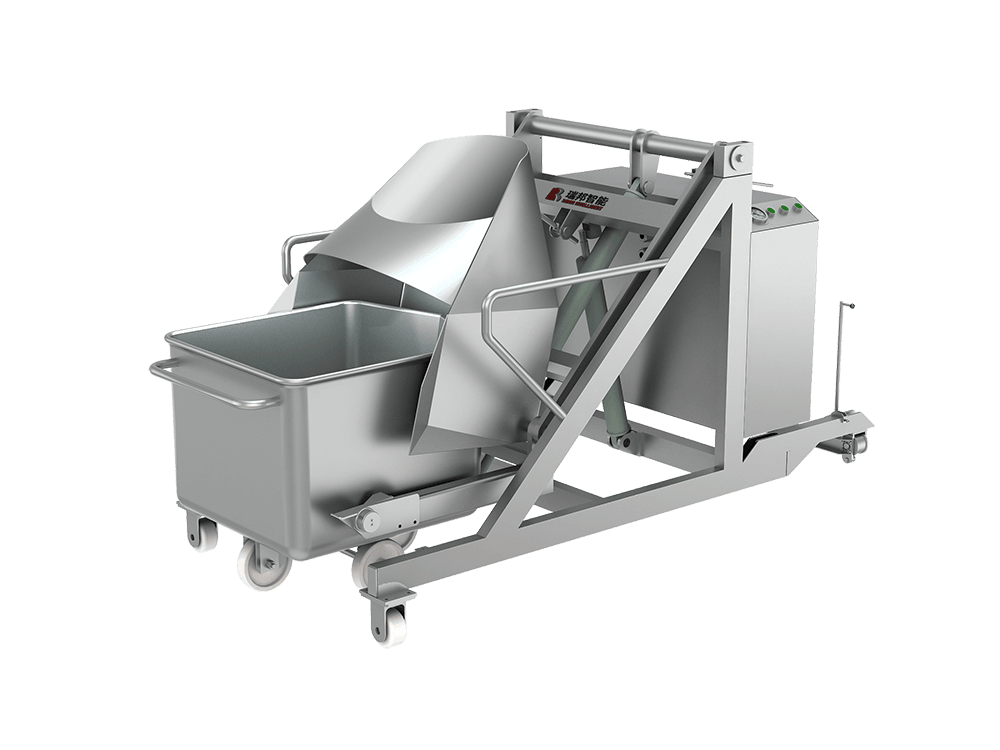

Hand wash basin & knife sterilizer is used in workshop for cutting meat products. It can be placed next to workers to facilitate hand washing and cutting tool sterilization.

●Characteristics:

◇The whole machine is made of SUS304, sturdy and durable.

◇Including electric heating and temperature controlling system.

◇The cutting tool sterilization box is optional.

◇Controllable water temperature.

◇The knife holder is made of nylon material to protect the cutting tools, and the knife holder is designed to be detachable, hygienic and easy to clean.

◇Reasonable design, no dead corners for cleaning, easy to clean

◇Using foot stepper, no need for hand operation, meets hygiene requirements.

Zhejiang Ribon Intelligent Equipment Co., Ltd. was founded in 2003 by Mr. Shi Ming and we specialize in the R&D and manufacturing of meat processing machinery. Meat Deboning Hand Wash Basin & Knife Sterilizer Suppliers and Company in China.

As a professional enterprise of meat processing smokehouse, vacuum tumblers and cutting and deboning lines in China, we also exported these solutions to the world since the year of 2003.

The technology and solutions have always been optimized and now Ribon's solutions are widely in use across the whole world. And we will constantly develop our systems further, to bring you better technologies and service.

The Allure of Smoke: Why Home Smoking is on the Rise The practice of smoking food—curing and flavoring it through exposu...

READ MORE

Have you ever wondered how commercial kitchens or butcher shops achieve incredibly tender, flavorful meats in a fraction...

READ MORE

In the pursuit of deep, intense flavor, the culinary world has continually sought faster and more effective marinating t...

READ MORE

The preparation of high-quality, flavorful meat products—from bacon and ham to poultry and processed cuts—is an exacting...

READ MOREProduct Knowledge